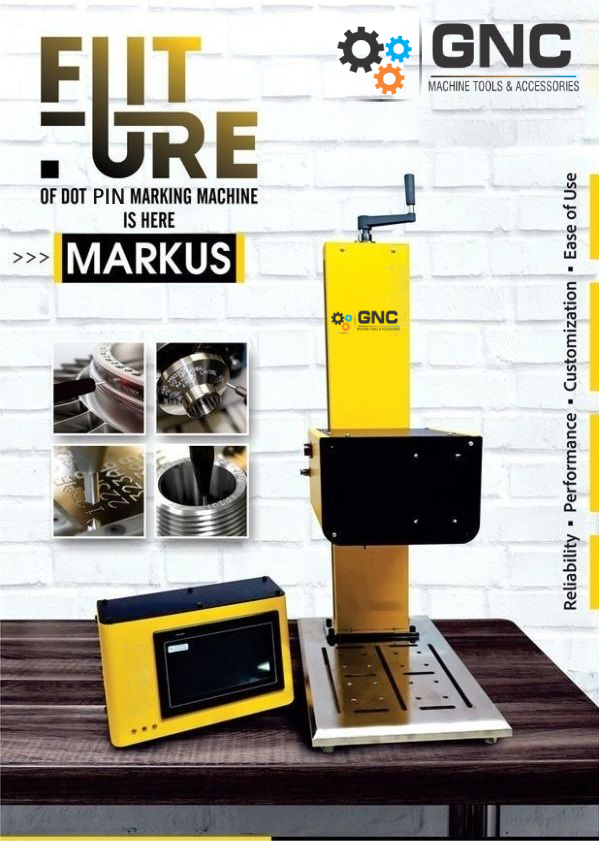

Dot Peen Marking Machine

Dot Peen Engraving Machine

Dot Peen engraving Machine allows manufacturers to make deep, permanent impressions in a variety of materials for identification and traceability. When programmed, Dot Peen can permanently mark human- or machine-readable information such as:

- Date/time stamping

- Part serialization

- Logos

- 2D Data Matrix bar code

- Operator identification

Our Specifications

BENEFITS OF OUR DOT PEEN ENGRAVING MACHINE

Why Choose Us

We @ GNC Marking

believe in Sharing of KNOWLEDGE that we have gained over a span of time in INDUSTRY, which would be helpful for young professionals.

[contact-form-7 404 "Not Found"]