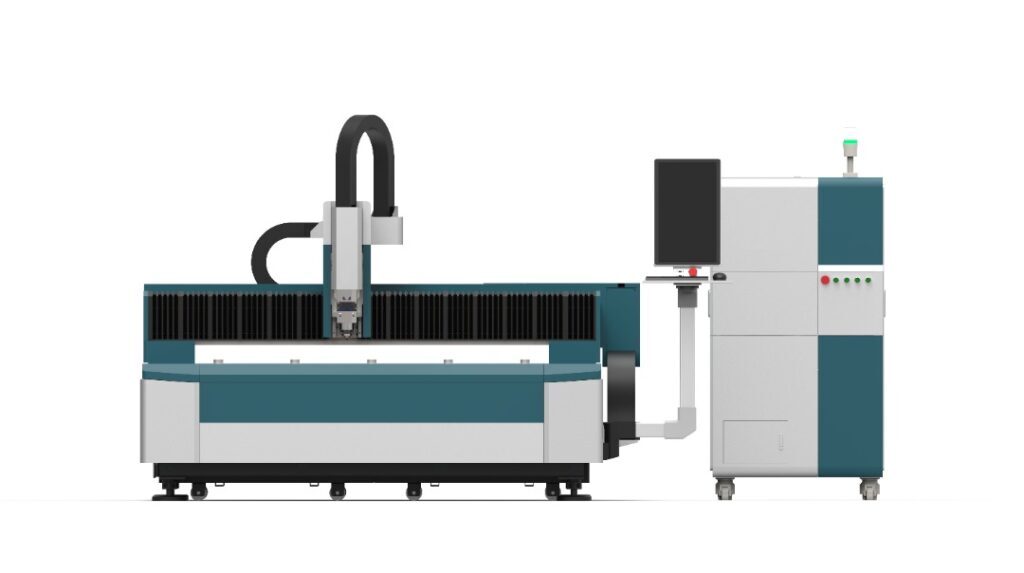

Laser Cutting Machine

Laser cutting is a permanent process that uses a beam of concentrated light to create a lasting mark on a surface.

Laser cutting can be automated and processed at high speeds, while leaving permanent traceability marks on a range of materials, including steel, titanium, aluminum, copper, ceramic, glass, etc

Our Specifications

BENEFITS OF OUR LASER CUTTING

Why Choose Us

We @ GNC Marking

believe in Sharing of KNOWLEDGE that we have gained over a span of time in INDUSTRY, which would be helpful for young professionals.

[]

1

Step 1